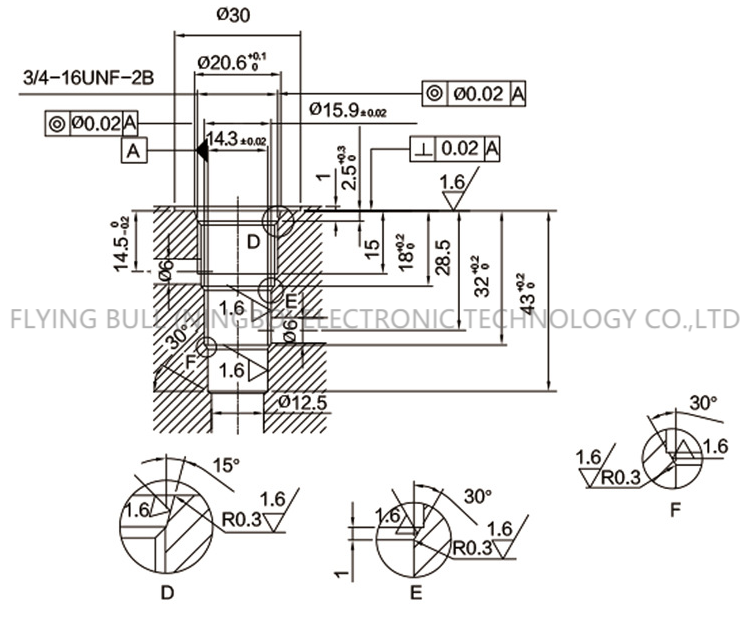

Matsayi biyu-hanya guda uku-hanya bawaka sv08-30

Ƙarin bayanai

Aikin bawul:bawaka shugabanci

Rubuta (wurin tashar tashar):Matsayi biyu

Ayyukan aiki:bawaka shugabanci

Tsarin kayan:alloy karfe

Yanayin zazzabi:yawan zafin jiki na yau da kullun

Jigilar Ragewa:commutate

Kayan haɗi na zaɓi:coil

Masana'antu masu amfani:kayan aiki

Nau'in Drive:sabbinku

Matsakaicin aiki:Kayan Petrooleum

Maki don hankali

1. Aiki mai aiki

Yana nufin ko ana iya dogara da lantarki bayan an ƙarfafa shi kuma ana iya sake saitawa ta dogaro da shi bayan an kashe shi. SOMENID bawul na iya aiki koyaushe a cikin wani yanki mai gudana. Iyakar wannan kewayon aikin ana kiran shi iyaka.

2. Asarar matsin lamba

Saboda bude bawul na SOLENOD karami ne, akwai babban matsin lamba lokacin da ruwa ya kwarara cikin tashar jiragen ruwa.

3. Yankunan ciki

A matsayi daban-daban na aiki, a karkashin matsin lamba na aiki, da zubar daga babban matsin lamba zuwa ga ƙaramin matsin lamba shine yaduwa. Rashin lalacewa na ciki ba kawai zai iya rage ingancin tsarin kuma yana haifar da zafi ba, har ma yana shafar aikin al'ada na mai aiki.

4

Lokacin washe lokacin carcondoid abu gabaɗaya 0.03 ~ 0.05 s, da kuma tasirin shago yana da girma; Lokacin bayar da kwalliyar DC SOMED VAVED shine 0.1 ~ 0.3 s, da kuma tasirin shago ne ƙanana. Yawancin lokaci lokacin sake saiti ya ɗan lokaci kaɗan lokacin.

5. Mitar wallafa

Mitar Waya ita ce yawan masu ba da izinin da bawul ɗin a lokacin. A halin yanzu, comtarfin comtard bawul na sodaloid tare da elecromagnet yana da sau 60 / min.

6. Sabunta Rayuwa

Rayuwar sabis na bawul na solenoid yafi dogara da lantarki. Rayuwar solderagromagton ya fi na bushewar electromaget, da kuma DC Elebrometnet ya fi na ACLelecromet.

A cikin man fetur, sunadarai, ma'adinai da kuma masana'antu na mitsi, bawul na hanya guda shida shine mahimmin na'urar juyawa ruwa. An shigar da bawul a cikin bututun mai isar da lubricating mai a cikin tsarin mai bakin ciki. Ta canza yanayin kambin secking na Majalisar A cikin jikin bawul din an haɗa shi ko cirewar bawul ɗin, don sarrafa juyawa da fara dakatar da ruwa.

Musamman samfurin

Bayanin Kamfanin

Amfani da Kamfanin

Kawowa

Faq