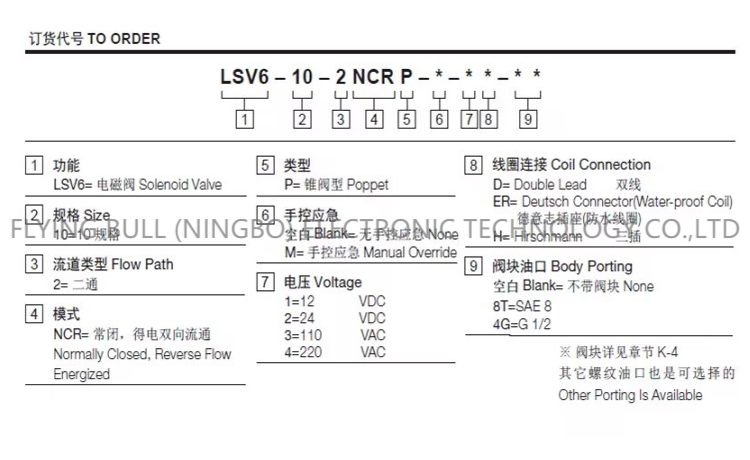

LSV6-10 2222 229CEMRP WABOUCT DOWNLORY KASHE RAYUWAR HYDRIALIGE

Ƙarin bayanai

Aikin bawul:daidaita matsin lamba

Rubuta (wurin tashar tashar):Nau'in aiki kai tsaye

Tsarin kayan:alloy karfe

Saka Albarka:roba

Yanayin zazzabi:yawan zafin jiki na yau da kullun

Masana'antu masu amfani:kayan aiki

Nau'in Drive:sabbinku

Matsakaicin aiki:Kayan Petrooleum

Maki don hankali

Bukatun fasaha na daidaitattun abubuwan da ke gudana

1 matakin zazzabi

Matsakaicin matsin lamba na cawul na gudana shine ƙayyadadden yanayin matsin lamba na harsashi na harsashi, indarealsalsalsals da kayan aikin bututu mai sarrafawa. Matsakaicin matsakaiciyar aiki mai amfani da kisatar kwaya a wani zazzabi shine karami na matsakaicin matsakaiciyar matsakaiciyar kayan aiki, masu zaman kansu da kayan bututun bututu a wannan zazzabi.

1.1 Matsakaicin matsin lamba na harsashi na baƙin ƙarfe zai cika GB / T17241.7.

1.2 Matsakaicin matsin lamba na harsashi na karfe zai cika GB / T9124.

1.3 Don kayan da aka ƙayyade matsayin da ake amfani da shi a GB / T17241.7 da GB / T9124, ƙididdigar ƙayyadaddun ƙirar ko tsarin ƙira za a iya bi.

2. Balawa Balve

2.1 Fuskar jiki mai bautar hannu, flange za a jefa shi tabbatacce tare da bawul. Nau'in da girman baƙin ƙarfe flanging zai cika GB / T17241.6, kuma yanayin fasaha zai cika GB / T17241.7; Nau'in da girman karfe flange zai cika a GB / T9113.1, kuma yanayin fasaha zai cika GB / T9124.

2.2 Dubi Table 1 don tsinkayen jikin bawul din.

2.3 mafi qarancin bangon kauri daga bawul jikin mutum mafi ƙarancin bangon ƙarfe zai cika tebur 1 a cikin JB / T 8937-1999.

3 Balbragm wurin zama

3.1 Nau'in haɗin tsakanin murfin bawul da kuma wurin zama na diaphragm, wurin zama na diaphragm da bawul. Zai zama nau'in flania.

3.2 Yawan haɗa kusoshi tsakanin kujerar diphragm da bawul na bawu ba zai zama ƙasa da 4 ba.

3.3 Mafi ƙarancin bangon kauri na murfin bawul da wurin zama na diaphragm zai cika bukatun 2.3.

3.4 Fuster da murfin bawul na bawul. Flange se secker surface na iya zama lebur, convex ko concave-convex.

4. Balawa da bawul, jinkirin rufe farantin bawul da kuma farantin bawul

4.1 Slow Mai saurin rufewa da bawul na rufe ya kamata a haɗa shi da tabbaci da dogara.

4.2 Nau'in hatimin tsakanin jinkirin rufe farantin katako da kuma babban farantin mara kyau yakamata ya dauki nau'in karfe.

4.3 Babban farantin karfe da bawul na bawul dole ya zame sassauya da aminci.

4.4 hatimi tsakanin farantin mai ban mamaki da babban wurin kwanciya na iya ɗaukar nau'ikan biyu: sutturar ƙarfe da hatimin ƙarfe.

Musamman samfurin

Bayanin Kamfanin

Amfani da Kamfanin

Kawowa

Faq